- Product Features

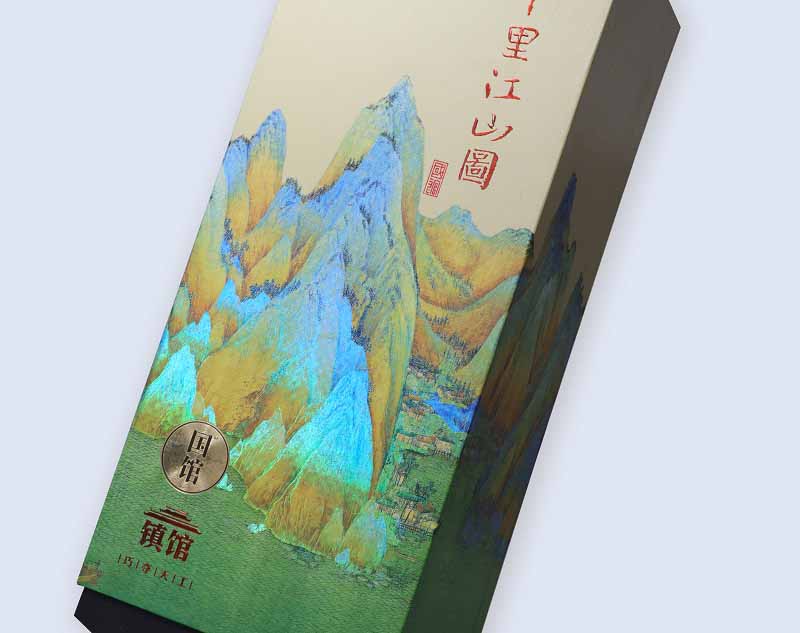

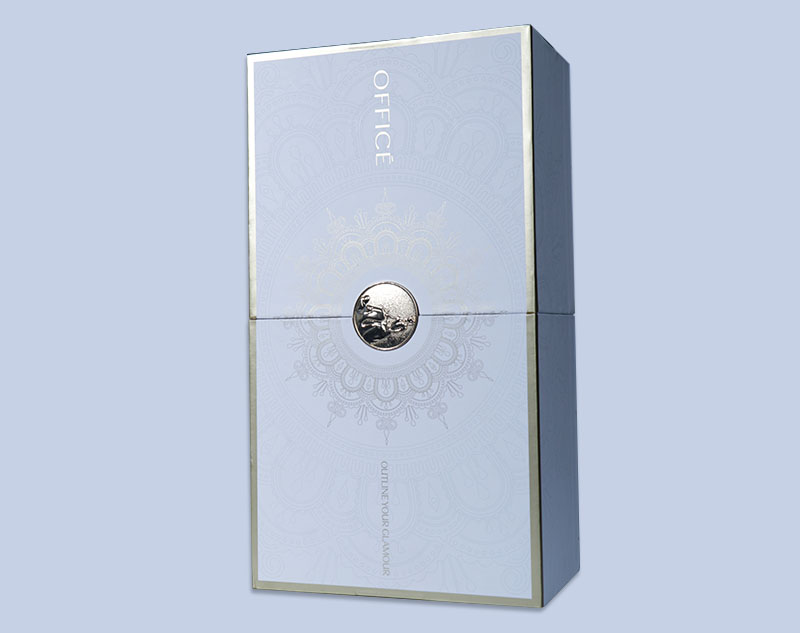

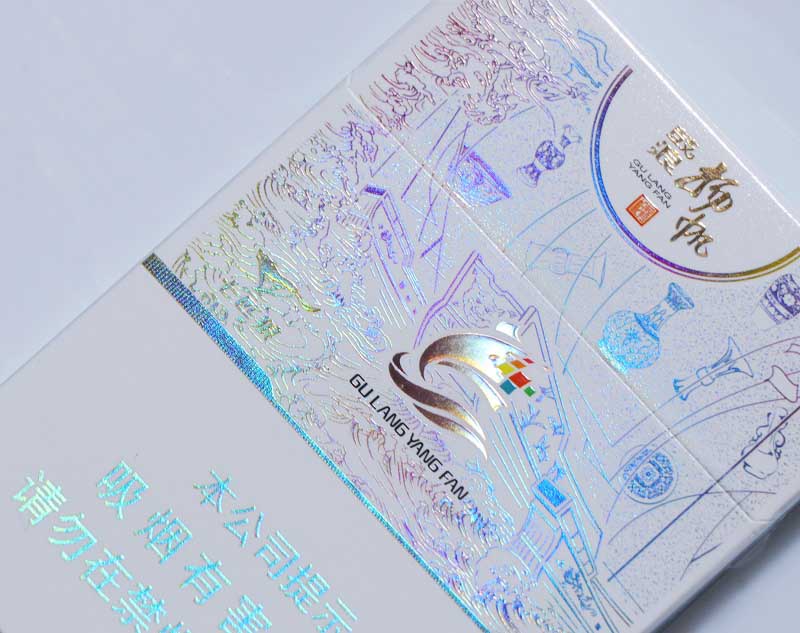

- Application Case

Main features of offset cold foil film

Low cost:

☆Low cost of cold stamping plate making, no metal plate is needed, only the existing printing plate is needed;

☆Cold stamping process does not require heating, low energy consumption;

☆Only need to install cold stamping unit, no need to buy large-scale equipment;

☆The material cost of cold stamping in big fields is 15% lower than that of gold and silver cards.(That can be achieved if the cold stamping design area reaches more than 40% )

Efficient:

☆Cold foil + printing in-line production, Offset printing + cold stamping is faster,(Maximum speed reaches 10000PCs/h),which is 2-3 times as hot stamping;It can also produce off-line.

☆Short plate-making time for cold stamping to satisfy customers for multiple quick proofing.

High degree of freedom of cold stamping designing and printing:

☆Can simultaneously meet the line, dot and field hot stamping effect(Lines can be as fine as 0.09mm、The dots can achieve 10%-90%、Stamping area on the ground can be 100mm*100mm);

☆Stamping before printing, can present colorful metal printing effect.

Environmental friendly: The raw materials used in the coating formulation are non-toxic and harmless; The product meets VOCs requirements; Use environmentally friendly water-based paint during the manufacturing process; No waste residue, waste gas, waste water discharge, and there is no environmental pollution.

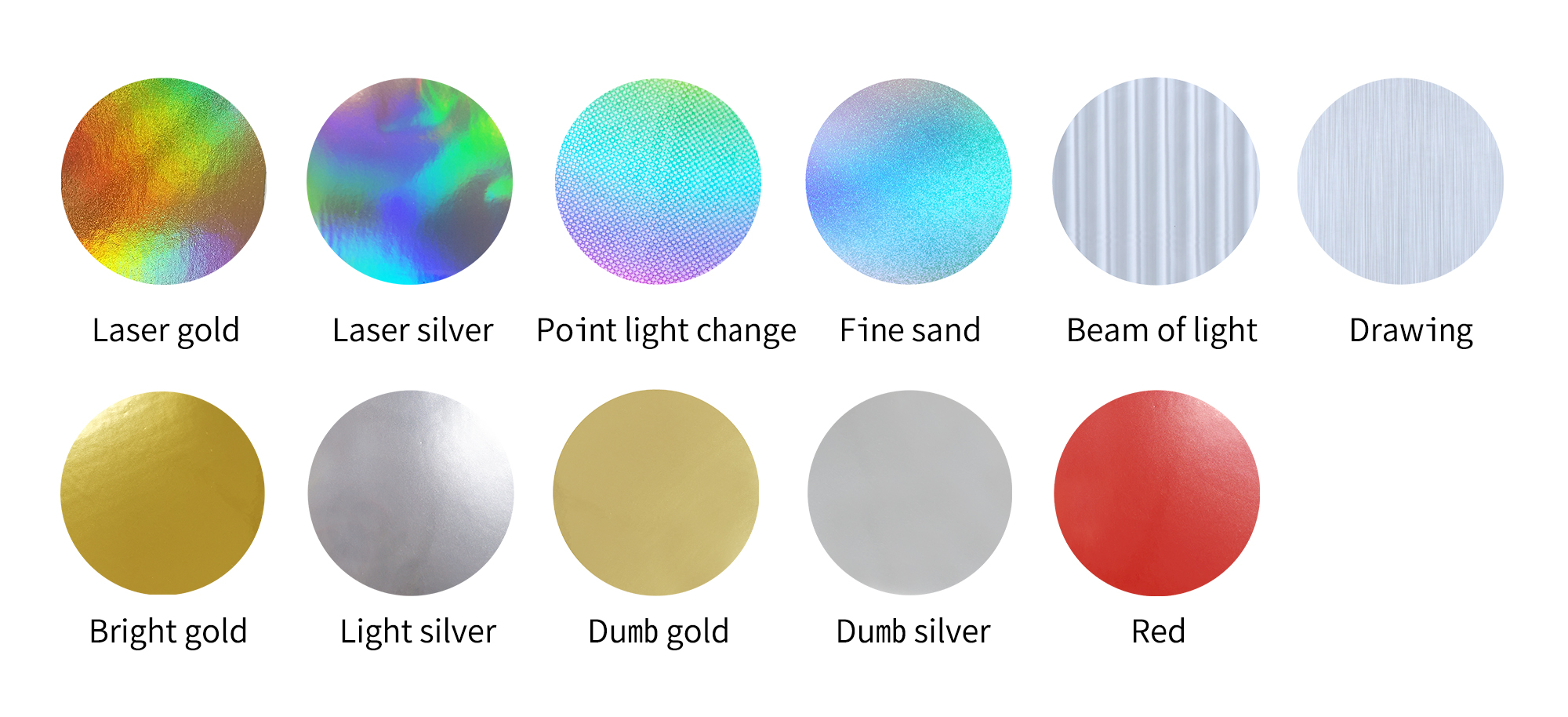

Cold stamping patterns are rich in colors:

Laser (plain surface, fine sand point, point-like light change, etc., as many as hundreds of laser patterns to choose from, Can also provide platinum effect cold foil film, transparent laser cold foil film);Non-laser (light gold, light silver, matte gold, matte silver, red, etc.).

Reference for application conditions of offset cold stamping film:

◆ Applicable substrate: Applicable to almost all offset printing substrates, such as: white cardboard, coated paper, laser gold and silver cardboard (laminated type, transfer type), film, etc.

◆ Applicable equipment: Applicable to almost all cold stamping equipment for offset printing, such as Evergreen, Roland, Heidelberg, Golden Magnolia, VINFOIL, etc.

◆ Applicable glue: Applicable to 90% cold stamping glues on the market, such as: Histar, Haizhonghui, Yuanhengli, Hanghua, Kurz, etc.

◆ Applicable field: The application on cigarette boxes is very mature, and the application on wine boxes and daily chemical boxes is also becoming mature/increasing/rapidly increasing.