- Product Features

- Application Case

Main features of flexo cold foil film

Simple cold foiling process:

Only need to install cold foiling unit;

Efficient:

☆Cold foil + printing in-line production, High-speed stamping.(Maximum speed reaches 150m/min );

☆Short plate-making time and cost for cold stamping to satisfy customers for multiple quick proofing.

Good stamping effect:

High metallic luster, strong laser effect, good surface printability after stamping;

High degree of freedom of cold stamping designing and printing:

☆Can simultaneously meet the line, dot and field hot stamping effect(Lines can be as fine as 0.09mm、The dots can achieve 10%-90%、Stamping area on the ground can be 200mm*200mm);

☆Stamping before printing, can present colorful metal printing effect;

☆Double-sided cold foil, both front and back have metallic effect.

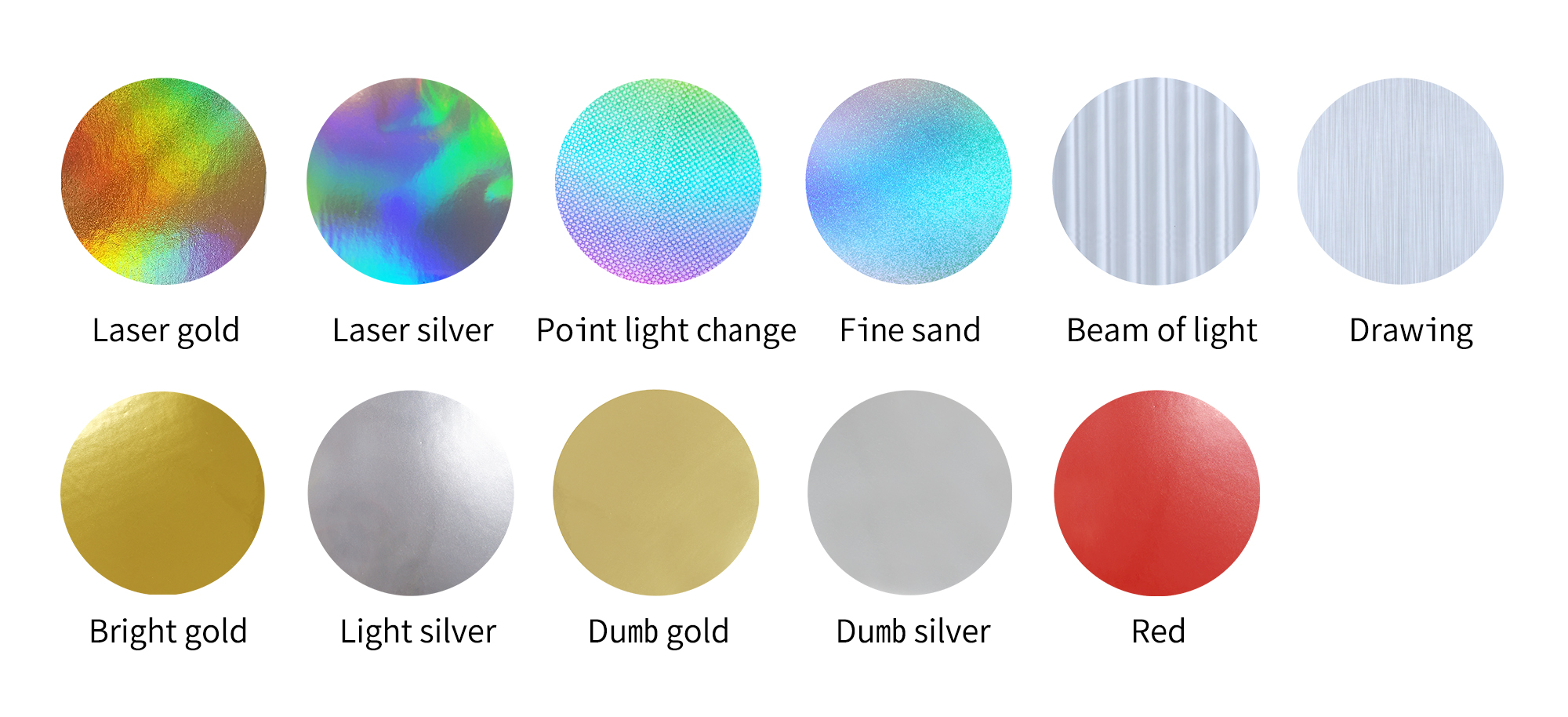

Cold stamping patterns are rich in colors:

Laser (plain surface, fine sand point, point-like light change, etc., as many as hundreds of laser patterns to choose from, Can also provide platinum effect cold foil film, transparent laser cold foil film);Non-laser (light gold, light silver, matte gold, matte silver, red, etc.).

Reference for application conditions of flexo cold stamping film:

◆ Applicable substrate: Suitable for almost all label substrates, such as: PE, PP, PET, coated paper and self-adhesive materials, etc.

◆ Applicable equipment: Applicable to flexo machines, full web machines, narrow web offset presses (PS plates) and other equipment equipped with cold foil units, such as: Mark Andy, Omet, Yuantie, Zhaolong, Weigang, Hongsheng, Zhongjing, Zhongte, Qianrun, etc.

◆ Applicable glue: Applicable to 80% cold stamping glue on the market, such as: Bright, Chaocai, Junjie, Hanghua, Flint, etc.

◆ Applicable field: Widely used in label printing, such as daily chemical labels, wine labels, food labels, beverage labels, internal membrane standards, etc.